Steel is an alloy of iron and carbon, containing less than 2% carbon.

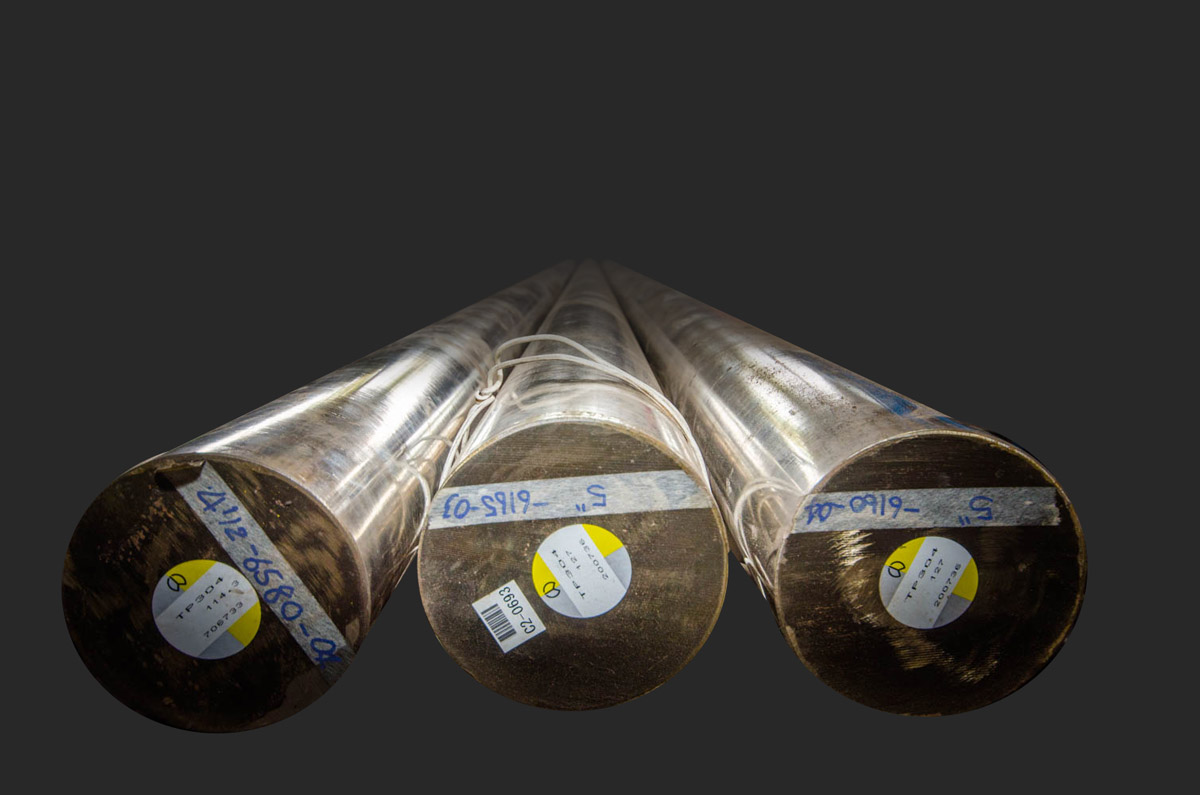

Stainless steel contains a maximum of 1.2% carbon, a minimum of 10.5% chromium (standard EN 10088-1) and other alloying elements. The presence of chromium confers on stainless steel its principal quality: its corrosion resistance.

The alloying elements, depending on their percentages, give stainless steels their physical, chemical and mechanical properties. The presence of alloying elements is the starting point for obtaining the desired properties, various production processes facilitating this. The carbon and iron steel base, together with the addition of various alloying elements, provide the balance of each grade and dertermine which stainless “family” it belongs.

The most frequently used alloying elements are: nickel, molybdenum, titanium, niobium, manganese, nitrogen, copper, silicon, aluminium and vanadium.